As studies and testing facilities are having greater numbers demanded of them, the requirement to utilize automation and high-throughput systems is becoming more and more common. To address these demands Isohelix has developed an exciting range of automation friendly high throughput tubes and caps designed to increase output and ease of use, using a universal design to fit various racking and robotic systems.

Read further to find out more information about the benefits and advantages of our automation and high-throughput tubes and caps and see how they can assist you in your next existing and future studies.

Unique 1D Barcode

All of our GeneFix Saliva Collection tubes include a unique 10 digit, alphanumeric 1D barcode on the side of the tube. This allows for full traceability of the sample from production through to distribution and testing.

We test our barcodes regularly to ensure that they are scannable on all common readers, including those widely available on mobile phones so that even patients at home can scan their devices to provide additional traceability.

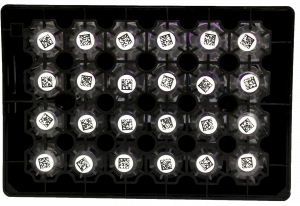

Corresponding 2D Barcode

Now available on our GFXH2 variants, the tubes can be specified with a 2D barcode on the base of the tube that corresponds with the 1D barcode on the side.

By having a 2D barcode available on the base of tube, this allows automation systems to scan the barcodes whilst in racking to maintain traceability whilst using high-throughput methods.

Fits Racks from Most Manufacturers

The design and dimensions of our automation friendly tubes have been specified to fit most widely available tube racks, meaning that they can easily be introduced to existing systems and methods without altering existing equipment or having to add new equipment. This means valuable time and effort saved in your study as well as the obvious financial savings from not having to invest in new equipment.

Automation Friendly Cap & Locking Base Design

All of the GFXH tubes have been designed with an automation friendly, auto-de-capping cap design that features both inner and outer grab facilities. Each tube also features a locking base design. All of these features allow high-throughput systems to remove the caps automatically, vastly reducing manual input requirements and processing times.

Email Us

Email Us